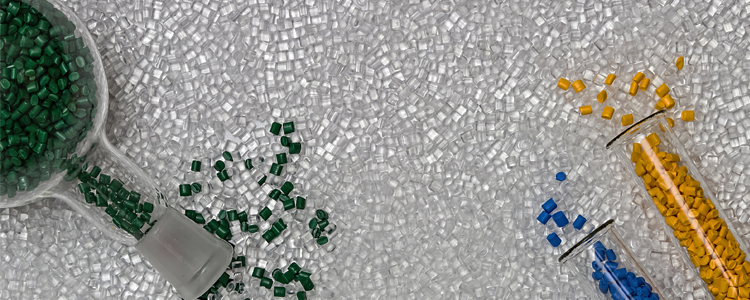

rPolycarbonate Granules

Polycarbonate Granules offered by us are manufactured using latest technology. These

Recycled Polycarbonate Granules find application in various industries due to their

superior quality. Available in different specifications, our Polycarbonate Granules

can be customized as per clients' specifications. The various qualitative features

of the Polycarbonate Granules together with their competitive price are the main

reasons for their high demand in the market.

Features

-

Strong

-

Stiff

-

Hard

-

Transparent

-

Transparent

About Polycarbonate

Polycarbonate (PC) is a linear polycarbonic acid ester prepared from a dihydric

phenol. Polycarbonate possesses extraordinarily good dimensional stability with a

high impact strength which is maintained over a wide temperature range. This makes

PC ideal for the manufacture of laboratory safety shields, vacuum desiccators and

centrifuge tubes.

PC Resistance

- Excellent resistance (no attack) to dilute

acids and mineral oils

- Good resistance (minor attack) to Alcohols and

vegetable oils

- Limited resistance (moderate attack and

suitable for short term use only) to Aldehydes

- Poor resistance (not recommended for use) with

Concentrated

- Acids, Bases, Esters, Aliphatic Hydrocarbons,

Aromatic Hydrocarbons, Halogenated Hydrocarbons, Ketones and Oxidizing Agents

Polycarbonate Fabrication

- Polycarbonate is one of the toughest

transparent sheets available

- Perfect for guards and glazing

- Polycarb machines well and brake forms cold

- Can be joined mechanically, solvent bonded,

and welded with lots of practice

- Typical uses include windows, machine guards,

and demonstration shields

Quick Facts